Little Known Questions About Sheroz Earthworks.

Little Known Questions About Sheroz Earthworks.

Blog Article

The Basic Principles Of Sheroz Earthworks

Table of ContentsThe Sheroz Earthworks IdeasAn Unbiased View of Sheroz EarthworksLittle Known Questions About Sheroz Earthworks.Sheroz Earthworks for BeginnersThe 7-Minute Rule for Sheroz Earthworks

This system enhances precision and effectiveness by a large margin. By making sure degree ground, it makes best use of safety for workers once the building procedure begins.Scratching functions rather like dozing, yet on a much finer and more exact range.

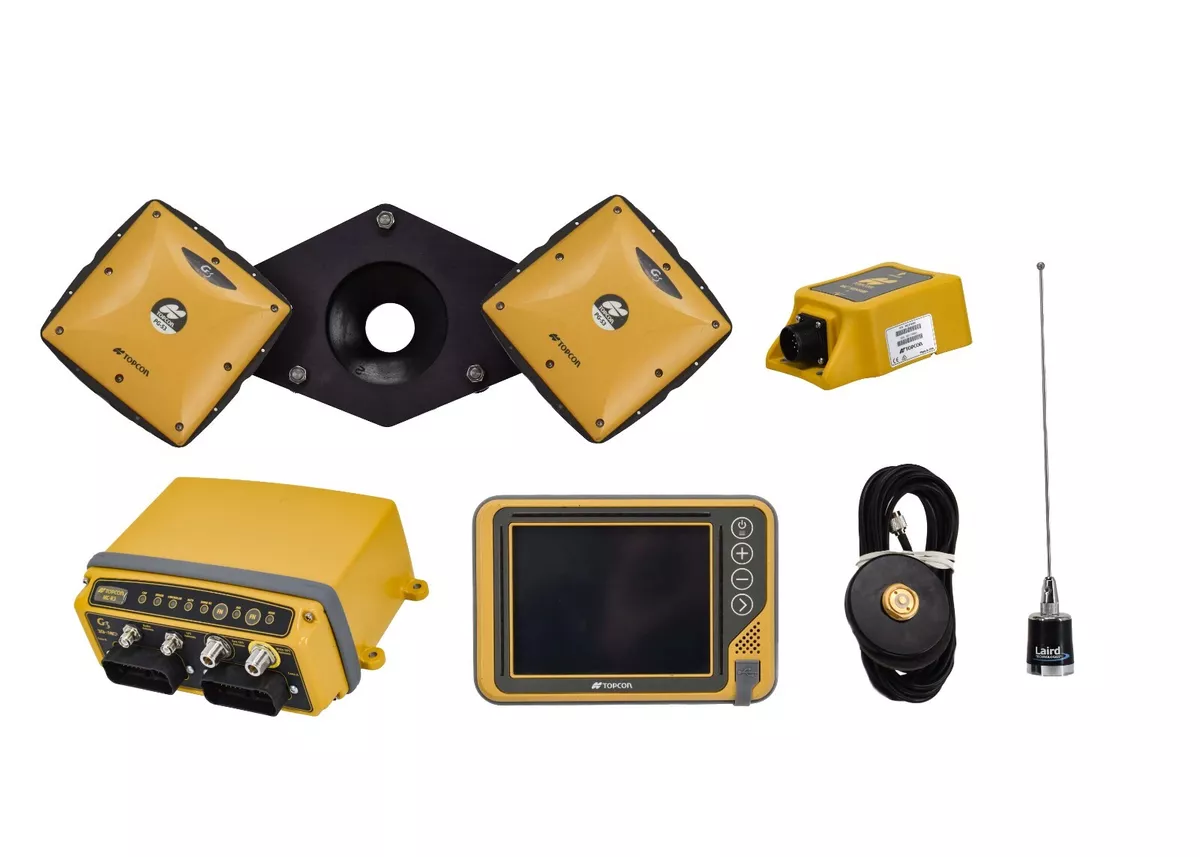

Device control can include worth to numerous farming jobs, consisting of: You can utilize the technology to without effort check and map field information in real time, making browsing and directing your devices simpler than ever before. Secret attributes consist of helped guiding that removes a lot of the burden from the driver, water monitoring, return tracking and video electronic camera input.

Machine control is tough enough for heavy area usage and provides the flexibility to perform several drainage system applications. Accomplishing maximum upright precision is vital when grading and developing land for farming. Maker control systems can handle this challenging application quickly and successfully, allowing you to increase productivity and minimize downtime in the field.

The Basic Principles Of Sheroz Earthworks

Experience quantifiable enhancements in essential locations like equipment and possession scheduling, fuel consumption and precautionary maintenance. Bolster work website safety and security and various other crucial processes by boosting accuracy and dependability in crucial mining procedures. Eliminate imprecise hand-operated area dimensions and increase reporting adaptability in your geotechnical and ecological surveillance programs with these sophisticated data-capturing services.

Whatever the emphasis of your most recent construction task is, you can benefit from equipment control. It can improve your progressing and hone your excavating, and it can do all of it while providing you feedback on where each vagabond gets on the website at any kind of given minute. As a movie director, you can utilize the system software application to see the entire website at the same time and observe every location that is being modified in actual time.

SITECH Southwest can get you the maker control system you require to transform your building and construction procedure (https://floydoverbeck4500.wixsite.com/my-site/post/elevate-your-projects-with-topcon-gps). As an accredited Trimble supplier, we provide top-notch tools for all the building refines noted above. Simply get in touch with us today to get your maker control system!.

Getting My Sheroz Earthworks To Work

For this to function, turning lasers were established to transfer signals that could be selected up by sensors placed on dozers or . This gave operators the standard info they needed for their devices. In contrast to contemporary machine control, these early systems were still extremely restricted at offering a full and precise photo and were additionally commonly also expensive or facility (topcon gps).

It is no key that there is a lack of fresh ability entering the sector. Particularly, service providers have difficulty drawing in young people and, consequently, there are fewer operators getting in the career. Ought to this pattern proceed, the market will certainly be entrusted to a lack of seasoned and trusted drivers, which suggests that the high quality and performance of tasks will certainly be impacted by a considerable skills space.

Surpassing merely offering operators with a visual overview to bucket or blade placement, automated machine control relocates the blade to grade by speaking with the device's hydraulics - fj dynamics auto steer price. Unlike with regular maker control, automated maker control technology puts the responsibility for precision and rate firmly in the hands of performance-enhancing modern technology

When taking a look at the present building landscape, it is clear that, in spite of its considerable advantages, equipment control automation is not being adopted throughout all makers at an equivalent rate. Although automation is being welcomed on equipments like and dozers, the uptake best site has been much slower for excavators, with the adoption price of automated machine control on these makers still estimated at around 10% in Europe in contrast to a rate of over 50% for dozers.

Not known Details About Sheroz Earthworks

Today, a rise in productivity on excavators can be kept in mind as increased precision and decreased over-digging being fairly easy to show. Nevertheless, it is clear that the sector currently requires to reassess the requirements for excavators. With the demands for efficiency increasing and a lack of proficient drivers, building needs to embrace the advantages that investing in automated device control can bring.

If you are looking to enhance your performance with today's innovation we are below to aid. Your existing team can be educated to do all elements of the set out and select up tasks of the everyday website demands in a no nonsense approach.

As expected, the excavator operators are under a significant stress to deliver an ideal efficiency while trying to achieve their productivity goals at the same time. That is why all type of aid and renovations are greater than welcome concerning raised precision and optimum manufacturing. As always, innovation is the trick.

The Sheroz Earthworks Statements

Report this page